Automatic transmissions have become the norm in modern vehicles, offering a convenient and comfortable driving experience. One of the critical components that make automatic transmissions possible is the torque converter. It plays a pivotal role in transmitting power from the engine to the wheels without the need for a clutch. In this blog, we will delve into their inner workings and understand their significance in automatic transmissions.

The Basics of Automatic Transmissions

Before we dive in, let’s briefly understand how automatic transmissions operate. Unlike manual transmissions, which require the driver to engage the clutch and shift gears manually, automatic transmissions do the shifting automatically based on the vehicle’s speed and engine load.

An automatic transmission consists of several components, including planetary gearsets, hydraulic systems, and the torque converter. Together, these components work in harmony to provide seamless gear changes and efficient power delivery.

What is a Torque Converter?

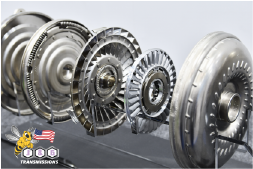

At the heart of an automatic transmission is the torque converter, a fluid coupling device that transmits power from the engine to the transmission. Its primary function is to transfer torque generated by the engine to the transmission input shaft, which eventually drives the wheels.

The torque converter operates using a principle of fluid mechanics. Inside the housing, there are three main elements: the impeller, the turbine, and the stator. These components work together to allow the torque converter to adjust its torque multiplication based on driving conditions.

How Does a Torque Converter Work?

When the engine is running, it drives the impeller, a curved blade fan located at the front of the torque converter. The impeller is immersed in transmission fluid. As it rotates, it creates a flow of fluid towards the turbine, which is connected to the transmission input shaft.

The rotating fluid from the impeller exerts force on the turbine blades, causing the turbine to rotate in the same direction as the impeller. This rotation, in turn, drives the transmission input shaft, allowing power to flow from the engine to the transmission.

However, the torque converter’s design allows for some slippage between the impeller and the turbine. This slip is particularly beneficial during idle or low-speed situations, as it prevents stalling and allows the engine to continue running even when the vehicle is stopped.

Lock-up Functionality for Improved Efficiency

To improve overall efficiency, many modern torque converters are equipped with a lock-up clutch. When the vehicle reaches higher speeds, the lock-up clutch engages, mechanically connecting the impeller and the turbine, eliminating the slippage. By doing so, the torque converter operates more efficiently, reducing heat generation and improving fuel economy.

Conclusion

The torque converter is a vital component of automatic transmissions, enabling seamless power transfer from the engine to the wheels without the need for a clutch. Its fluid coupling design allows for smooth gear changes and prevents stalling during idle or low-speed situations. Additionally, the lock-up functionality improves efficiency, contributing to better fuel economy in modern vehicles.

Next time you drive an automatic transmission-equipped vehicle, take a moment to appreciate the role of the torque converter, working diligently behind the scenes to provide you with a smooth and enjoyable driving experience. As technology continues to advance, we can expect further refinements in design, leading to even more efficient and responsive automatic transmissions. More info on transmission installation

and repair can be found on our Pro page: https://jandgtransmissions.com/automotive-pros/

Videos

Check out this video on how torque converters work: https://www.youtube.com/watch?v=z5G2zQ_3xTc

Common Mistakes with Torque Converter installation: https://www.youtube.com/watch?v=Buz27CTac7k&t=1s